Competitive Price JS3000 Concrete Mixer Js3000 Forced Type Twin Horizontal Shafts Automatic Cement Concrete Mixer Made In China

FOB Price: US $29,900 - 37,000 / Set

Min.Order Quantity: 1 Set/Sets

Condition: New

Introduction of js3000 concrete mixing machine

Features of js3000 concrete mixing machine

E-mail:

FOB Price: US $29,900 - 37,000 / Set

Min.Order Quantity: 1 Set/Sets

Supply Ability: 100 Set/Sets per Month

Port: Qingdao, Tianjin, Shanghai

Payment Terms: L/C,T/T,Western unio,MoneyGram,Paypal, Credit card, Cash

Condition: New

Place of Origin: Henan, China (Mainland)

Brand Name: Jianxin

Model Number: JS3000

Motor Power: 55 KW

Mixing Power: 60 KW

Charging Capacity: 4800 L

Reclaiming capacity: 3000 L

Speed of Mixing Drum: 21 r/min

Water Supply Mode: Water Pump

Working Cycle Period: 60s

Discharge Way: Hydraulic Discharging

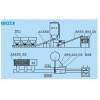

Outline Dimension: 4050*2680*2150 mm

After-sales Service Provided: Engineers available to service machinery overseas

Product name: js3000 3 yard large capacity concrete mixer

Theoretical output: 150 CBM/Hour

Mixing blade rotating speed: 21 r/min

Max grain diameter(gravel/grait): 100/120

Mixing blades: 55*2

Color: Yellow or customized

Shaft type: Twin horizontal shafts

Key feature: Hermetic condition for all procedures

Advantage: Automatic lubrication system

Application: All industrial or civil construction projects

Packaging & Delivery

Packaging Details: 1, For full container load, main body with plastic film surrounded or in nude, key parts and spare parts in strong export wooden or iron case. 2, For less than container load, main body and all spare parts in strong export wooden or iron case.

Delivery Detail: Usually in stock, Shipped in 7 days after payment

Introduction of js3000 concrete mixing machine

Combined with domestic and overseas advanced techonology, JS concrete mixing machine can work individually or to be simple concrete mixing plant with PLD series batching plant, also could provide matching host for mixing plant. So it is a widely used and high efficiency model. JS3000 concrete mixing machine is reasonably designed, easy for use and maintanance. Also can be customized according to your personalized request. JS3000 has wide applications, such as all kinds of factories for prefabrication, roads, bridges, irrigation works, wharf and other industrial or civil construction projects. Could mix hard concrete, plastic concrete, fluidity concrete, light orthopaedic concrete and all kinds of mortar.

Working principle of js3000 concrete mixing machine

•The break motor drives rotation of the coiling block, when the hopper climbs up to a certain height by loading track, the hopper door will open automaticlly, and raw materials will be put into the stirring pot.

•There are limit switches on loading shelf to assure the accurate position of the hopper. JS3000 heavy duty concrete mixer has 2 limit switches on upper limit positon, seperately offers positioning and protection for the hopper. Also there is 1 limit switch on lower limit position.

•The loading shelf of js3000 could be folded for easy transportation.

Features of js3000 concrete mixing machine

•Reasonably designed with nice appearance, quick assembling and disassembling, convenient transportation.

•Various layout forms to adapt different sites.

•Js forced type concrete mixer adopts twin horizontal shafts, with high mixing quality and efficiency for kinds of concrete.

•Powdery materials are processed in hermetic condition in all procedures including loading, burdening, measuring, charging, mixing and discharging. There is a high quality dust remover in the main mixing pot, also the mixing pot and belt conveyor are sealed. Vastly reduced dust and noise pollution.

•JS3000 concrete mixing machine has double mixing blades quantity compared with common twin shaft horizontal mixers. Outter ring pushes material to be boiling status, while inner ring shovel shears in radial direction, realize violent and sufficient mixing for material in a short time.

•Electrical opening style or pneumatic discharging, avoid the shortcoming of raw material remaining.

•Optimal designed hopper, easy to clean, better charging ability.

•Prompt and neat discharging.

•Easy for use and maintanance.

•Automatic lubrication system.

E-mail: