Quick Detail :

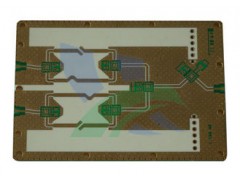

1. Type : Pcb

2. Material : Rogers

3. Layer : 4

4. Products Size : 7*7cm

5. Permittivity : 3

6. Surface finish : Gold Plating

Features:

1. Rogers pcb multilayer pcb with high frequency can improvide the products quality ,with high techolonogy treatment improve the life cycle of the products .

2. Immersion gold surface finish make the pcb 's conductive performance enhancements.

3. Multilayer pcb design ,the precision of the pcb improves much more better .

4. Low dielectric : 3 dielectric conductivity much more precision .

Description :

RO3000® high frequency circuit materials are ceramic-filled PTFE composites intended for use in commercial microwave and RF applications. This family of products was designed to offer exceptional electrical and mechanical stability.

RO3000 series laminates are circuit materials with mechanical properties that are consistent regardless of the dielectric constant selected. This allows the designer to develop multi-layer board designs that use different dielectric constant materials for individual layers, without encountering warpage or reliability problems. The dielectric constant versus temperature of RO3000 series materials is very stable.

Typical Applications:

- Automotive radar applications

- Global positioning satellite antennas

- Cellular telecommunications systems - power amplifiers and antennas

- Patch antenna for wireless communications

- Direct broadcast satellites

- RFID Tags

- Surface mount RF components

- E-Band point to point microwave links

Production Description :

| XCE PCB technical specifications | ||

| Annual stock Material | Rogers,Taconic,Arton,Isola,F4B,TP-2.FR-4,High TG,Halogen free | |

| Layer No. | 1~16 | |

| Min board thickness |

2 layer0.2mm 4 layer0.4mm 6 layer 0.6mm 8 layer 0.8mm 10 layer 1.0mm |

|

| Max panel size | 508*610mm | |

| Board thickness tolerance | T≥0.8mm±8%.,T<0.8mm±5% | |

| Wall hole copper thickness | >0.025mm(1mil) | |

| Finished hole | 0.2mm-6.3mm | |

| Min line width | 4mil/4mil(0.1/0.1mm) | |

| Min bonding pad space | 0.1mm(4mil) | |

| PTH aperture tolerance | ±0.075mm(3mil) | |

| NPTH aperture tolerance | ±0.05mm(2mil) | |

| Hole site deviation | ±0.05mm(2mil) | |

| Profile tolerance | ±0.10mm(4mil) | |

| Board bend&warp | ≤0.7% | |

| Insulation resistance | >1012Ωnormal | |

| Through-hole resistance | <300Ωnormal | |

| Electric strength | >1.3kv/mm | |

| Current breakdown | 10A | |

| Peel strength | 1.4N/mm | |

| Soldmask regidity | >6H | |

| Thermal stress | 288℃20Sec | |

| Testing voltage | 50-300V | |

| Min buried blind via | 0.2mm(8mil) | |

| Outer copper thickness | 1oz-5oz | |

| Inner cooper thickness | 1/2 oz-4oz | |

| Aspect ratio | 8:1 | |

| SMT min green oil width | 0.08mm | |

| Min green oil open window | 0.05mm | |

| Insulation layer thickless | 0.075mm-5mm | |

| Taphole aperture | 0.2mm-0.6mm | |

| Special technology | Indepedance,Blind buried via,thick gold,aluminum PCB | |

| Surface finish | HASL,Lead free HASL,Immersion Gold, Immersion Tin, Immersion Silver,OSP ,ENIG ,Golden finger,Blue glue,Gold plating | |