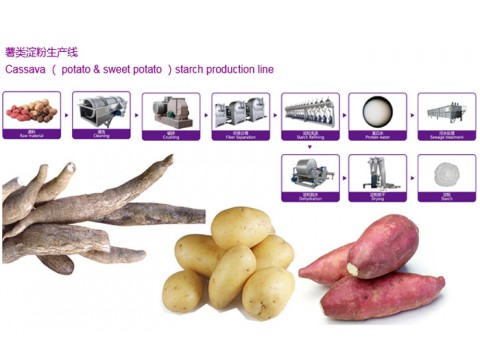

Sweet potato starch production line flow chart

The decription of sweet potato starch production line:

Step 1. Sweet potato starch production line- Screw Conveyor

Usefulness of screw conveyor: Clean and carry potato to Cage Washer.

Features of screw conveyor: Driven by speed adjustable motor, flow rate can be automatic from long-distance. on top of the spray pipe can take all the dust and sludge form the cassava, the adjust motor can adjust the row material in put speed 100% guarantee all the row material clean out.

Step 2. Sweet potato starch production line-Cage Washer

Usefulness of Cage Washer: Clean potato up the hull, sand, muddy or other sundries.

Features of cage washer: Low power consumption, big capacity, well cleaning results, stable operation, and friendly maintenance. Use the rotation speed to take out the row material shuck.

Sweet potato starch processing machine-- hammer crusher

Step 3. Sweet potato starch production line-Hammer Crusher

Usefulness of Hammer Crusher: In order to increase of service life, hammer is soldered to cemented carbide. The screen mesh is durable service for 2mm thickness.

Features of Hammer Crusher: Low energy consumption, high capacity, fine particles, easy installation, and friendly maintenance. Hammer crusher use high speed to crusher all the material to the smaller piece.

Sweet potato starch production line

Step 4. Sweet potato starch production line-Roundness Sieve

Usefulness of Roundness Sieve: Separate plasm and dregs.

Features of Roundness Sieve: Good separation effect, small energy consumption and less construction cost advantages.

Step 5. Sweet potato starch production line-Starch Residue Extruder

Usefulness of Starch Residue Extruder: Easy to dry starch residue after being squeezed

Features of Starch Residue Extruder: Convenient operation, saving energy, no vibration, high output, and easy maintenance.

Step 6. Sweet potato starch production line-DesanderUsefulness of Desander: To remove sand, or other sundries.

Features of Desander: Low power consumption, convenient operation, and friendly maintenance.

Sweet potato starch production machine

Step 7. Sweet potato starch production line-Purified Hydrocyclone Assembly

Usefulness of Purified Hydrocyclone Assembly: Purify and extracte starch in staech process. Multistage cyclone station whose primary purpose is the removal of soluble and insoluble protein, fine fiber, the end of the purification of sugar starch milk. Is concentrated, washing, key equipment of refined starch.

Features of Purified Hydrocyclone Assembly: It has multifunction of concentration, recover, washing, and separation for the Purified Hydrocyclone Assembly

Sweet potato starch production machine-- vacuum degydrator

Step 8. Sweet potato starch production line-Automated Vacuum Dehydrator

Usefulness of Automated Vacuum Dehydrator: Solid-liquid vacuum dewatering machine dewatering starch is widely used in medicine, food, chemical and other industries separation All the equipment is made of high quality stainless steel, rotating drum speed frequency can be controlled There is paddle stirrer inside the filter in case of the sedimentation of starch. Scraper blade is made of high quality hardness alloy. The device absorbs the foreign advanced technology, stable operation, compact, low power consumption, small size, good performance, dehydration rate, no noise, easy operation and maintenance, is ideal for medium-sized enterprises in starch production.

Sweet potato starch production machine--starch dryer

Step 9. Sweet potato starch production line-Air Flow Dryer Assembly

Usefulness of Air Flow Dryer Assembly: TYPE QZWG Air-stream crash dryer, is a kind of new energy-saving drying equipment, which is declared as Chinese national invention patent. The main fuel is coal or gas. The freezing air becomes dry hot blast through the hot air-stream stove, which is appearing as suspended state with bulk material. It causes the gas and solid to go forward at higher speed in parallel. At the same time the water is vaporized in order to dry material.

This sweet potato starch production line can produce starch 5t ,10t ,20t,30t,50t,100t .