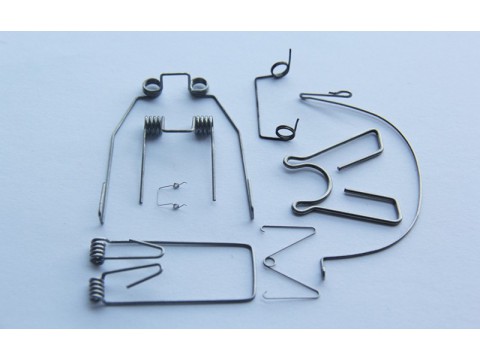

AFR Precision Technology Co.,Ltdis committed to the continuous improvement of thespringsservice, become a society, customers, shareholders and employees long-term trust of the company. Our Company adhering to pirit of for the sake of customers, and win-win with customers , and through AFR Precision staff continuous innovation and development to provide first-class torsion spring replacement,Best selling torsion spring manufacturer,Unique precise torsion springs,precise torsion springs traffic ranking for enterprises , is what we have been working for. Details:Precision torsion springs can be found in many day-to-day applications, such as clothespins, ratchets, window shades and other types of machine components.Precison torsion Springs work by resisting externally applied torque. Friction and arm deflection affect torque. Precision torsion springs are most effective when supported over a rod or tube.Double torsion springs consist of one right-hand and one left-hand coil section connected to each other and working in parallel.We frequently manufacture both plain-end torsion springs and those with multiple complex bends. Precision torsion springs are most commonly manufactured from round wire. Available in wire diameters of .005 inches to .3175 inches in a variety of raw and pre-plated materialsWe manufactures custom precision wire forms, metal stampings, coiled springs (or compression springs) torsion springs and product assemblies that are utilized throughout the medical, aerospace and industrial markets.With the fast development in physical Human-Robot Interaction (pHRI), researchers have been focusing on compliant joints to ensure the safety of humanity. Series Elastic Actuator (SEA), basically consisting of a motor in series to a spring connected to the load, is an effective solution of compliant joints. In this paper, a novel flat torsional spring with corrugated flexible units for SEA is proposed to meet the requirement for the elbow joints of humanoid robots. Then a series of tests are performed in Ansys Workbench 15.0. Under 30 N-m torque, the torsional angel is 0.105 rad. The torsional stiffness is 288.5 N· m/rad. Compared to the simulation results of other existing flat torsional springs, the proposed structure has a lower torsional stiffness, which provides workers a better protection. What's more, it has a higher radial stiffness and a higher axial stiffness, which decreases the vibration and increases the control accuracy.

With the rapid development of business simultaneously, AFR Precision always keeps the balance between external opportunities and internal management, attaching great importance to the training and shaping of core competitiveness. The company will take customer service value as the core competitiveness of enterprises. Adhering to spirit of enterprise:acting with integrity , pursuit of excellence, respect for the individual , AFR Precisionstrives to provide customers with Honest and reliable wire form spring exporter. More details in the AFR Precisionofficial website: www.afr-precision.com