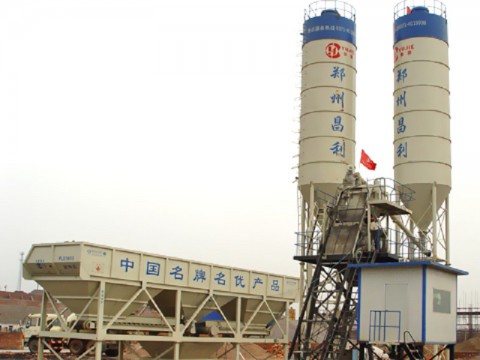

HZS50 Small Concrete Mixing Plant

Application:

HZS50 concrete mixing plant is a fully automatic concrete mixing equipment. The mixing station has small floor space, flexible installation and high production efficiency. It can be widely used in road and bridge terminals, water conservancy and hydropower, small and medium-sized construction projects, etc. select.

Features:

1. Advanced mixing host

HZS50 concrete mixing plant adopts advanced JS1000 mixing host, adopts high wear-resistant alloy mixing arm process, and the service life is 3-5 times of ordinary mixing arm;

2. Modular batching station

Single warehouse module, freely combined, symmetrical, and loaded on both sides, convenient and flexible;

3. Ring beam type powder tank

The powder tank adopts the ring beam type design, and the leg body is connected with the ring beam, which is safer and more reliable;

4. Strong environmental performance

Professional dust collector and secondary dust collection design, powder tank dust collection rate of 99%.

Product parameters:

HZS50 concrete mixing plant

|

HZS25 |

HZS35 |

HZS50 |

||

|

Rated productivity |

25m³/h |

35m³/h |

50m³/h |

|

|

Mixing host |

Model |

JS500 |

JS750 |

JS1000 |

|

|

Host power |

18.5KW |

30KW |

2x18.5KW |

|

|

Productivity |

25m³/h |

35m³/h |

50m³/h |

|

Batching unit |

Model |

PLD800 |

PLD1200 |

PLD1600 |

|

Power |

6.6KW |

11KW |

12KW |

|

|

Maximum weighing value |

Aggregate |

1200kg |

2000kg |

3000kg |

|

Cement |

300kg |

400kg |

600kg |

|

|

Water |

150kg |

250kg |

250kg |

|

|

Admixture |

40kg |

40kg |

40kg |

|

|

Measurement accuracy |

Aggregate |

±2% |

||

|

Powder |

±1% |

|||

|

Water |

±1% |

|||

|

Admixture |

±1% |

|||

Product details:

Pre-sale service

1.Assiste customers to select the suitable type of mixer

2.Designe and manufacture products according to the special requirements of customers.

3.Engineers and technicians go to the place of users to design the workshop, the best process and project for the users

In- sale service

1. Inspection and acceptance of mixer equipment.

2. Assist customers to draw up construction plans.

After-sales service

1. Organize, coordinate and implement after-sales service for users who order equipment.

2. Organize relevant departments of the company to collect customer feedback, formulate implementation plans in time and solve practical problems of customers.

3. More than 40 professional technical after-sales service personnel stationed abroad for long-term customers tracking service.

4. Provide spares parts and other accessories for users in time.