Product Introduction

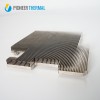

Skived Fin Heatsinks is a manufacturing process where thermal solutions are formed by shaving one solid block of copper or aluminum into a finned heatsinks.

Design Flowchart

Custom Heat pipe Heat sink, Copper heat sink Supplier, heatsink OEM service.

Technical Parameters

|

Materials 1.Aluminum 1050/1060/1070 2. Copper CDA110 |

Specifications 1.4 foot max profile width 2.<= 10 in profile length 3.40:1 fin height to minimum gap ratio 4.<= 150 mm maximum fin height 5. 0.1 – 1.0 mm fin thickness |

Applications

Limited space Forced airflow Servers Networking/Telecom boards

|

Benefits

1.High fin densities 2.Perfect conductivity between base & fins 3.Great forced airflow solution 4.Low tooling cost |

Pioneer Thermal products mainly include CNC machining, cold forging heatsinks, cold plate, die casting heatsinks, extrusion heatsinks, heatpipe assemblies, skived fin heatsinks, stacked fin heatsinks, folded fin heat sinks

Any heatsinks and skived heatsinks, please contact Pioneer Thermal. We'll reply you within 12 hours.

Email: sales@ptheatsink.com

vivian@ptheatsink.com

Our Customers

Our most of products are customized and widely applied in IPC,server,telecom & communications infrastructure &power,LED lighting,medical equipment and other products.

Shipping Methods

Any cold forging heatsinks services, please contact Pioneer Thermal. We'll reply you within 12 hours.

Help your design design team to improve the part for manufacture.(design refine/process optimize/cost reasonable)