Poultry feed pellet making maker has the characteristics of compact structure, gorgeous appearance, large diameter of feed opening, ring pass away style, suitable for making feed pellets, high outcome, reduced power consumption, hassle-free use and trusted working efficiency. The stress rollers are equally set up, and the procedure is steady.

At the same time, the pressing location is increased, and the manufacturing performance is improved. The screw facility pressure managing structure is embraced, and the space in between the mold and mildews rises and lowers, and also it is suitable for various materials to ensure the pressing result.

1. The range of application of the fowl feed pellet making equipment:

It is widely utilized in huge, medium as well as small tank farming, grain as well as poultry feed plants, livestock farms, fowl farms, private farmers and little and also medium-sized ranches, farmers or large, medium and also little poultry feed processing plants.

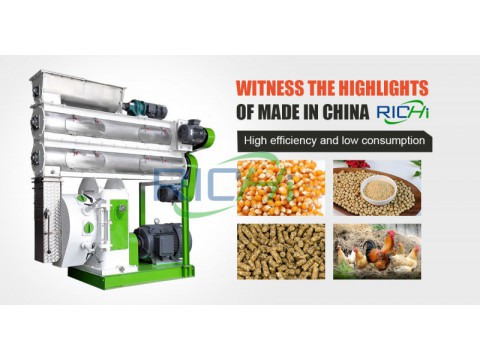

The following is a detailed intro to the RICHI chicken feed pellet making maker.

( 1) Resources of poultry feed pellet making maker:

Feed processing equipment that straight presses pellets with smashed products such as corn, soybean meal, straw, lawn, rice husk, etc.

( 2) The working principle of the chicken poultry feed pellet making machine:

RICHI fowl feed pellet making device achieves the goal of feeding dry in and also dry. Via the extrusion between the pressing roller as well as the die plate, the temperature level of 80 ° C can be gotten to during the manufacturing process, and the pellets with smooth surface area as well as consistent body can be processed. As well as have a certain hardness. In addition, individuals can choose various apertures as well as compression proportions according to their different needs to get the best modern technology and financial advantages.

The fowl feed pellet making machine uses a electric motor as the driving shaft for power, as well as runs cyclically on this basis. It drives the major shaft through gears to rub the die plate and the pressure roller, and the resulting rubbing temperature level ( in between the pressure roller and also the die plate) can be up to 80 ° C. The raw product goes through the heat, under the extrusion of the pressing roller and the die plate, and also passes through the holes on the die plate, as well as the high-quality molding pellets will turn out from the discharge port.

Related case: Uzbekistan 3-5T/H Feed Plant For Poultry

(3) Advantages of feed pellets produced by RICHI chicken pellet machine:

High hardness, smooth surface area as well as internal ripening, which can improve the digestion and absorption of nutrients. The pellet formation process can denature the pancreatic enzyme resistance factor in grains as well as beans, lower the adverse impacts on digestion, kill different bloodsucker eggs and other pathogenic microbes, and also reduce different insects and also gastrointestinal system conditions. Compared to blended powder feed, higher financial benefits can be gotten.

( 4) R&D strength of Richi Equipment:

The fowl feed pellet making device is a brand-new sort of energy-saving devices independently established by Richi Equipment. Richi Equipment has a first-rate R&D team, which consists of the chicken feed pellet making equipment research and development task division, the biomass pellet device research and development job department, and the natural fertilizer pellet maker research and development job division. Job Department. Richi Machinery has actually progressed equipment manufacturing devices, solid development toughness and excellent after-sales service. It is a professional manufacturer of pellet machinery in China that looks into, develops, manufactures, installs as well as debugs.

2. The rate of fowl feed pellet making maker

The cost of poultry feed pelleting machine is typically 7000-100000USD, as well as the outcome of chicken feed that can be refined is 1-48t/ h. If the grass-containing feed is to be refined, the yield is somewhat reduced, and these are determined according to the customer's actual resources and also solutions.

More details: https://www.pellet-richi.com/feed-pellet-machine/poultry-feed-pellet-machine.html

3. Why choose RICHI chicken feed pellet making maker?

( 1) RICHI Equipment feed pellet maker has actually passed a variety of patents and also won a number of license certifications.

( 2) It has actually passed the international ISO9001 and EU CE accreditation, as well as is a new power equipment production enterprise encouraged by the state.

( 3) All models have actually passed the agricultural equipment promo appraisal of the Ministry of Agriculture, and all of them have passed the evaluation.

( 4) Some districts and also areas have actually passed the nationwide agricultural machinery acquisition subsidies, and the purchase of farming machinery can take pleasure in government aids.

( 5) Richi Equipment establishes year by year, products are regularly upgraded, advanced handling equipment, charming craftsmanship, and also stringent inspection and also testing make sure better of products. The poultry feed pellet making equipments are around the nation as well as exported to Europe, America, Asia, Africa, etc international market.

( 6) Perfect after-sales service, all buyers only require to rely upon the "product quality warranty card", you will certainly appreciate 1 year warranty and also life time maintenance after-sales service.

( 7) The chicken feed pellet making equipment created by Richi Equipment have won the titles of "Famous Products" and also "Quality Trustworthy Products" for sometimes.