Overview and Principles:

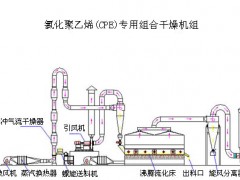

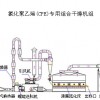

Our company according to the material properties of chlorinated polyethylene, designed a special combination of dryer, fluidized bed using air drying and boiling combination, effectively extends the drying time, increase the drying efficiency, product quality has been greatly improved. Equipment by air heating systems, feeding systems, pulse flow drying host, received powder system, boiling bed, fan and control system, etc.. Dry and wet materials by drying pipe feeding within the player into the pulse was high-speed hot air to break up to move, full access to the materials and air, the material in the water is quickly evaporated, so that the material becomes more viscous flow of good loose material. Materials collected through the separation device into the boiling fluid bed. In a fluidized bed, the flow of materials from a longer drying time, thus ensuring the quality of the dry material.

Features:

1 , Yields a large, continuous production, high degree of automation

As the material in a highly decentralized state, drying, fast drying and high yield. Drying process with automatic temperature control system, operation, just set the drying temperature, the control system to automatically adjust the temperature, the temperature difference In "/span> 5

Total: 0 [Show All] Related Reviews