Import Philips infrared heating infrared light source lamp Philips --- , lamp , heat lamp , animal lamp ,

light therapy main features:

Infrared radiation heating source is a direct way to transfer heat wave heating method, using infrared heating technology is the only - kind of non-contact, target heating, no air and water heating technology as a delivery medium. The heat transfer rate as the speed of light is about 300,000 km / s. Therefore, the full use of the infrared (wavelength 0.78 - 4 um) can achieve high power.

Scope:

Can be rubber, plastic, glass, printed circuit board, body, metal, casting, leather, food and other materials for heating, drying, evaporation, softening, hardening, forming, activating, voltage level, sterilization, baking and other processing; can be a variety of powder coatings, water-based paints, primers, overlay coatings, paints and dyes, ink, film, glazing, paste, glue and adhesives to cure.

several categories infrared radiation heating source characteristics:

HF - high power, high penetration force. Has a very high power, radiation can be focused on the goals and to provide efficient heat, because it can reach full capacity within a few seconds of work intensity, so the short-wave radiation heating source is ideal for quick stop and start the process.

Fast medium wave - a stable, efficient, responsive breaking.

AM - efficient and economic. Can be quickly heated surfaces and thin, and have characteristics that can be rapidly absorbed water film, Compared with the short-wave radiation, especially for medium-wave drying process.

concrete can be summarized as follows:

application areas: special infrared lights, high quality, high thermal efficiency, power density, power consumption and long life. Products with infrared reflective coating can further improve the thermal efficiency.

mainly used in:

1. Glue and ink curing;

2. PET blow molding, laminating;

3. Wood drying and spray before preheating;

4. Soften plastics and synthetic, cable production;

5. Activation of the glue drying;

6. Baking paper drying;

7. Dry and light cleaning glass;

8. Paint baking and local vehicle repair;

9. Food baking, heating and insulation;

10. Circuit boards, capacitors, semiconductor production;

11. Space heating, infrared therapy, central air conditioning of water and drying.

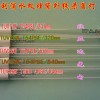

attached: PHILIPS (Philips) List of infrared heat source model specifications