AZS Refractory Block is manufactured by using high purity alulmina powder, zircon sand and silica raw material with ceramic and chemical bonding. AZS refractory block usually be used to build glass kiln and repair.

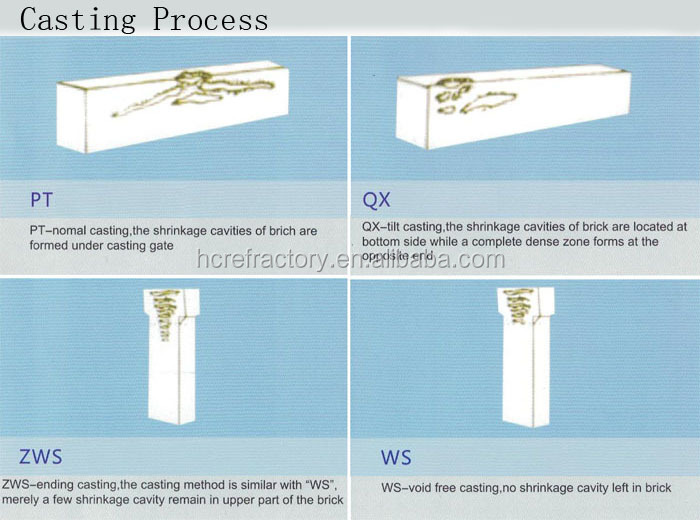

AZS Refractory Block Casting Method

AZS Refractory Block have four usual casting method like PT, QX, WS, and ZWS. Each casting method has its own casting features. For example, PT casting method, normal csting, cavity is located under the casting scar; QX casting method, the cavity is located at the rear bottom side; ZWS is reinforced casting, reduced cavity loacted at the bottom of the block, while the WS is total filling with no cavity as the cavity zone will be sawed off.

AZS Refractory Block Freature

1. No shrinkage cavities

2. Low apprant porosity

3. High corrosion resistance

4. No pollution on glass liquid

5. Long service life about 10 years or above

6. Strong mechnical strength

7. High refractoriness under load

8. Good thermal shock resistance

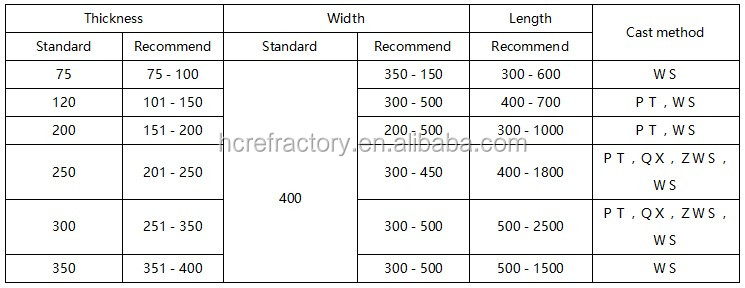

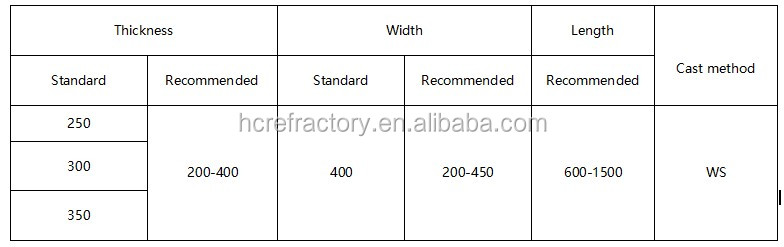

Dimension of AZS Refractory Block

Dimension of AZS Refractory Brick AZS 33# Block (unit:mm)

Dimension of AZS Refractory Brick AZS 36# Block (unit:mm)

Dimension of AZS Refractory Brick AZS 41# Block (unit:mm)

More Detail about AZS Refractory Block

AZS Block-33

AZS Block-33 are excellent in preventing the pollution of glass liquids. The possibility of causing glass stones, bubbles and basic glass phase precipitation is quite slim. It can be applied to the upper structure of melting pool, the tank wall corner tiles,paving bricks and other approaches as well.

AZS Block-36

AZS Block-36 are the standard Fused Cast AZS Refractory bricks brick which boasts of the quality of particularly high corrosion resistance of glass liquids and low pollution. More than that, it has a balanced performance in the above two aspects. It can be applied to the direct access of glass furnace and glass liquids, such as melting tank wall corner tiles, paving bricks and charging door.

AZS Block-41

AZS Block-41 are the best oxidated zircon corundum brick which possesses the quality of highest corrosion resistance of glass liquids and excellent low pollution of glass liquids. It can be applied to the locations of glass furnace which requires particularly high corrosion endurance, such as full-fused furnace, liquid pumps, furnace ridge, bubbling brick and bricks of charging door corners.