Ployurethnae Screen

Details:

Fine polyurethane shale shaker screen

Fine polyurethane shale shaker screen has a extremely fine openings, which is trapezoidal. It can prevent plugging and blocking during separating the materials. Additional, the fine opening can supply more accurate screening in the applications.

Specifications

- Material: urethane.

-

Mesh opening:

- Wet panel: 0.25" × 325 mesh

- Dry panel: 0.25" × 140 mesh.

- Open area: 35% – 45%.

- Lifespan: 6–12 months.

Features

- Large open area.

- Superior capacity and performance.

- Low operating and maintenance cost.

- Easy to install and uninstall.

- Durable and long service life.

- Practically non-blinding.

- Can be repaired or patched in place.

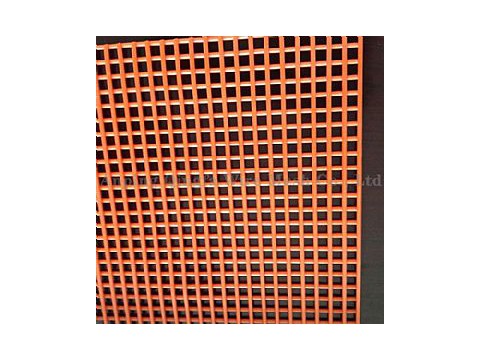

Modular screening

Polyurethane Modular screening is an extremely adaptable system. This system can be a permanent flat deck, which is fixed on the frame or removable modular solution using modular tension mats. The fastening accessory provides substantial locking area.

Specifications

- Panel size: 12" x 24" or 12" x 12".

- Mesh type: slot opening and square opening.

- Mesh opening: 1/64" – 3/1/2".

- Sheet thickness: 30 mm – 70 mm.

- Longer life. It has 15 to 20 times life of wire cloth.

- lower plugging and blinding and better production performance.

- Various materials available: Etchers, esters at 60A – 90A hydrometer.

- Easy installation.

- Flexible installation options.

-

The first method:

- Install the frame onto the machine in advance.

- Place the modular screening into the frame along one edge.

- Strike the opposite edge with a mallet, which will be delivered along with the screening. Strike the modules continuously until all the modules are in position.

-

The second method:

- Install the modules onto the frame according to the first method.

- Then install the frame with modules onto the machine until all are installed.

Compared with modular screening, tension mats is easier to install and replace. Just fix the tension mats through hooks on the two side. The hook can be metal or polyurethane for different machine and applications. You can replace a tension mats in seconds and the whole system in minutes. And it need no special tools.

Specifications

- Material: polyurethane or rubber.

- Reinforcement: cable or steel tube.

-

Size:

- Maximum Over-hooks Dimension: 3.5 m.

- Maximum Width Dimension: 1.525 m.

- Mesh opening: max. 2.5".

- Color: yellow, blue, red and other colors can be customized.