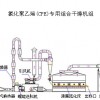

1, process description:

Wet material through the crowded strip machine extruded into strips with a dryer after the fall on top of feeding segment, with the net with the forward movement of strip material to be uniform net ground floor in the dryer belt, net with the constant speed driven gear to move forward, the net to bring the material from the feeding port side sent to the other end, then fall into the second belt, the second layer of mesh material through the post into the bottom belt, and then brought out from the bottom of the feed material, in this process by the drier material through the internal flow of hot air drying, so that material loss of moisture.

Hot air drying section by the number of independent cycle modules, some of which exhaust gas discharged from the air vents, both transfer valves in each unit displacement control. In the cycle unit, hot air circulation fans in the circulation under the effect of the heat from the stove to provide, through the heat vent into the cell, so that drying temperature is kept within a certain range. Hot air drying process through the material layer is complete the heat transfer process.

Second, design features:

1 , Drying equipment, reasonable structure, easy control, energy conservation, no dust pollution, meet the national environmental standards.

Equipment designed to mesh with the three-tier approach, according to materials in different stages of drying characteristics of a flexible set of different drying parameters, in the upper, the higher moisture content of materials can be expected to implement the smaller shops and fast web thickness with speed; at the bottom, the material moisture content decreases, the larger shops can be expected to implement the thickness and slower belt speed, to extend the residence time of materials to make materials fully dried. Hot air inside the device through a three-tier network of belt materials, heat transfer to fully achieve the purpose of energy efficiency; the top layer of material with high relative humidity, dust produced a small amount of dust emitted from the exhaust port is relatively small, achieve energy reduction. Each unit of equipment are the inlet (the first and second floors of each unit has the inlet, the first three modules have the inlet of each layer), each of the inlet valves with the adjustment of wind Liang Jun, Jin with sub-tuyere air blade, effectively ensuring the uniformity of hot air and can control nature.

2 , Equipment, production of high quality stainless steel interior, with clean-up box on the door, clean up is very convenient and durable.

3 , With both sides with stainless steel mesh baffle can effectively prevent the fall of materials during the drying process.

4 , Spindle bearings installed in the box outside, avoid high temperature environment;

5 , Fan and fan drive motor spindle with belt drive, to avoid overheating of the motor;

6 In the box relatively sealed environment designed to prevent hot air leakage;

7 , Materials are extruded forming machine drying with less advanced networks to improve drying efficiency and exhaust gas efflux was reduced to a minimum level of dust, dust removal equipment installation can be achieved without good results;

8 , Hot air into the air volume can be adjusted, and with sub-air devices to ensure that hot air evenly;

9 , Exhaust from the row, reducing heat loss and exhaust gas dust content;

10 , And equipment transmission parts with access door, and easy maintenance.

Third, production description: annual output of 5,000 tons, 10,000 tons, 15,000 tons, 20,000 tons, 30,000 tons

4, supply of equipment:

Complete offers, including heat, auxiliary equipment, drying equipment, shredders, etc., specific bilateral talks.

5, sales performance:

Three users in Guangdong and other places 10.